2016

On August 12, 2016, the tenth anniversary since the OPAL (Open Pool Australian Light-water) reactor achieved criticality was celebrated. This multipurpose facility, particularly oriented to radioisotope production, was designed and built by INVAP. It is located on the premises of the Australian Nuclear Science and Technology Organization (ANSTO) in Lucas Height, Sydney. The Australian reactor became fully operational in November 2006 and was officially inaugurated in April 2007.

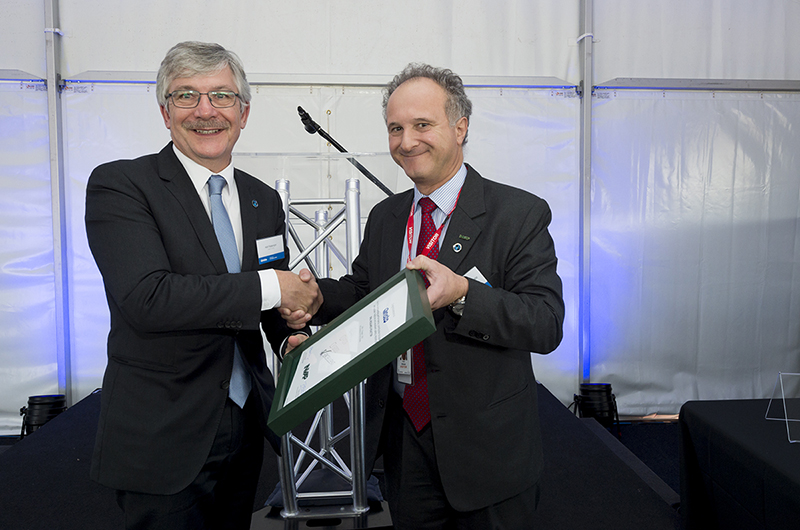

The celebrations to commemorate this anniversary were held on August 8. Several authorities were present, such as the General Director the International Atomic Energy Agency (IAEA), Mr. Yukiya Amano; the Minister of Industry, Innovation and Science of Australia, Mr. Craig Laundy; and the Manager of the Nuclear Projects Area of INVAP S.E., Engineer Pablo Abbate. The latter gave to the CEO of ANSTO, Dr. Adi Paterson, a diploma for the outstanding performance of the OPAL reactor, its contribution to science and nuclear medicine, and its excellent safety record.

OPAL is one of the most complex research reactors in the world and the major technological export of a turnkey plant in the Argentine history. It is also the largest investment that Australia has ever made in a single scientific and technological project. Winning the international tender of this important project showed at the moment the competitive level achieved by the Argentine nuclear technology.

INVAP is today internationally recognized as a supplier of reliable and up-to-date nuclear technology for peaceful purposes, and it has become a member of the leading group in developing and building research facilities and equipment, including research nuclear reactors and radioisotope production plants. To carry out the OPAL project INVAP led a large group of Argentine and international contractors. The Argentine National Commission of Atomic Energy (CNEA, in Spanish) deserves a special recognition not only for taking part in the project, but also for encouraging the national nuclear industry.

Besides providing Australia and other countries with radioisotopes, the OPAL reactor offers silicon irradiation services to the microelectronic industry. The reactor has provided quite efficient services and has become one of the most reliable and available in its kind worldwide. It has been fully operational 307 days a year, which is an unbeaten record. This excellent performance has been carried out complying strictly with the international regulations’ requirements on nuclear safety.

OPAL’s uses

OPAL is a state-of-the-art reactor that uses low enriched uranium fuel to achieve a wide range of goals in the fields of nuclear medicine, scientific research, industrial services and radioisotopes production. It is used by members of the scientific, medical, environmental and industrial communities, as well as by Australian universities.

The applications of neutron science are virtually unlimited and OPAL is extremely versatile in this respect. It has been especially designed to put into practice neutron research carried out by the Bragg Institute, a world-renowned research center that, thanks to this reactor, is making countless contributions to science and industry.

- It has in operation 13 highly complex instruments, considered among the best of their kind worldwide, to carry out studies that use neutron beams produced by OPAL.

- More than 200 scientists and technicians work in its facilities with the data provided by the OPAL’s instruments. Together with the permanent staff, more than 1,000 visiting scientists and members of the international scientific community conducted last year a research using these instruments.

- More than 1,000 scientific publications on neutron science have been published by ANSTO.

- It encourages industrial development and research, and the management of technology transfer to the industry. It also provides support to a wide range of industries in the mechanical, optical, microelectronic, energy, chemical, food and environmental fields.

- The unique properties of the neutrons provided by OPAL and the instruments of the Bragg Institute are used by their scientists to study the structural integrity of big engineering components, such as shovels for wind turbines used in power stations.

- It is now producing 2 million doses of medical isotopes a year with great potential for saving lives. These compounds are used to diagnose and treat a wide range of conditions including cancer, coronary diseases and skeletal damage in patients from Australia and the rest of the world. Every week, ANSTO provides more than 250 Australian hospitals and medical centers with 10,000 doses. The molybdenum 99 produced by OPAL, the isotope more frequently used in cancer treatment, is exported to different countries, such as U.S.A., China, Japan and South Korea, among others. The organization capacity allows exportations to be doubled if needed.

- Thanks to OPAL, ANSTO offers silicon irradiation services to microelectronic industry companies, making it the silicon irradiation world-leading provider (45% of the market) to Asian and European companies. The OPAL facilities are able to satisfy the current increasing demand of irradiation of silicon ingots with a diameter of up to 20 cm. The silicon irradiated at OPAL is also used for manufacturing microelectronic devices employed in energy-related infrastructure, hybrid vehicles, high-speed railway trains and the development of renewable sources of energy.

- It plays a vital role in the mining industry through the analysis of concentrated sand samples using neutron activation techniques.